This offer is currently only addressed to commercial customers. All prices are exclusive of goods and services tax (GST).

_5_0.svg)

INTRODUCTION

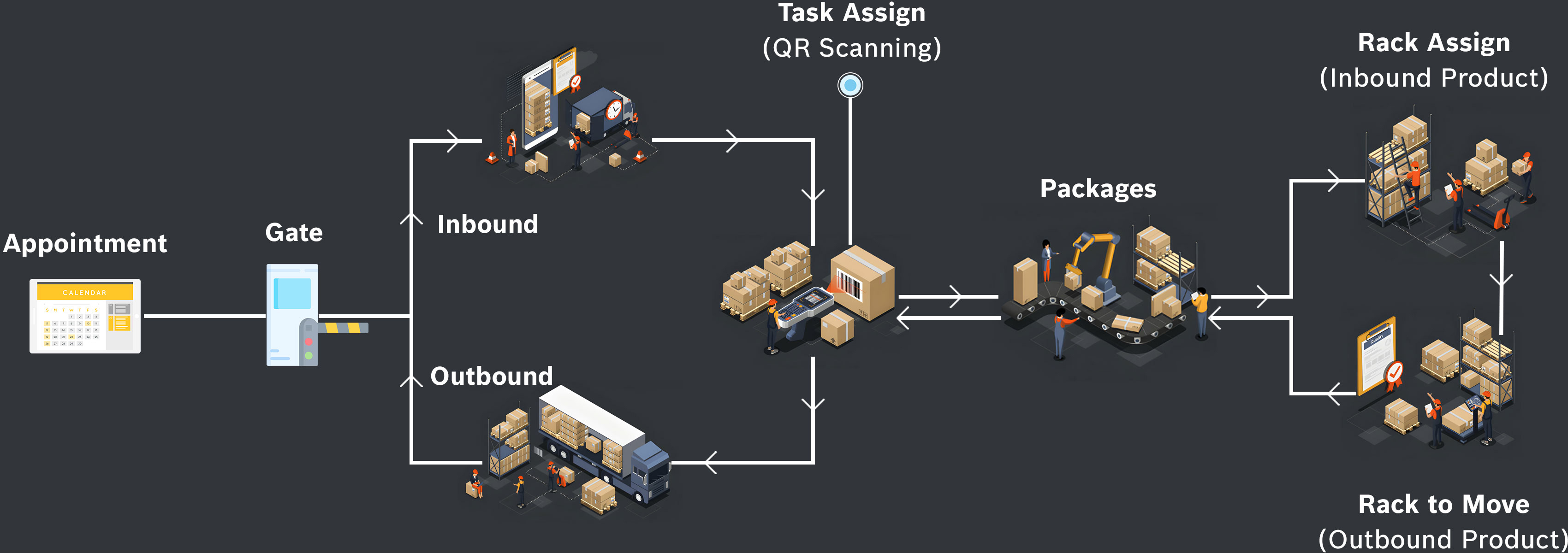

Touching on the pain points the logistics ecosystem faces, BOSCH Warehouse Management System has been designed to improve efficiency, scale up warehousing operations at your pace and help enhance productivity. Let’s elevate and try achieving seamless flow throughout the ecosystem.

INBOUND PROCESS

- ASN Creation: Our goal is to enable users to effortlessly create, receive, and upload Advance Shipping Notices (ASNs) within our system.

- Planning and Scheduling of Incoming Goods: Our aim is to facilitate the efficient planning and scheduling of incoming goods based on their priority, ensuring a streamlined workflow.

- Resource Planning: Our objective is to develop features that help in planning the allocation of personnel and equipment as per specific operational requirements.

- Document Verification: Cross-validation of documents for better accuracy.

- Goods Receipt: Receiving and confirming the arrival of goods by scanning a QR code and cross-referencing it with the provided ASN.

- Quality Inspection: Capable of approving or disapproving the goods following a quality inspection.

- Equipment Allocation: Automatically allocating handling equipment for enhancing the efficiency.

- Auto Allocation of Racks/Bins: Automatically assigning storage racks and bins based on a put-away strategy.

- Routing Optimization: Our objective is to enhance internal routing processes to improve the movement of personnel responsible for storing items in the designated racks or bins.

- Put Away Confirmation: Confirming the placement by scanning the barcode on the rack.

INVENTORY MANAGEMENT

- Tracking: Our aim is to provide continuous monitoring of goods for accurate and up-to-date information.

- Cycle Counting: Periodically auditing and counting a subset of inventory items.

- Batch Management: Our goal is to offer robust tracking and management capabilities for groups of products, commonly referred to as batches.

- Bin-to-Bin Transfer: Moving items within the warehouse from one storage location to another.

- Stock Consolidation: Merging inventory from multiple locations for efficient storage.

- Repacking: Altering packaging or quantities of items for efficient handling.

OUTBOUND PROCESS

- Order Processing: Receiving, validating, and preparing customer orders for fulfillment through integration with the client's ERP system.

- Pick List Generation: Creating lists specifying items to pick for order fulfillment.

- Resource Planning: Our objective is to develop features that help in planning the allocation of personnel and equipment as per specific operational requirements.

- Routing and Route Optimization: Optimizing the Picker's movement, guiding them from their current position to the assigned rack or bin for picking, and subsequently directing them to the temporary outbound storage area after the picking process.

- Packing Strategies: Our software will employ various packing strategies such as FIFO, FEFO, or LIFO to optimize the packing process for customer orders.

- Packing List Generation: We are developing functionality to generate packing lists, ensuring that items are packed accurately and efficiently for shipment.

- Shipment Manifest: Creating and managing shipment manifests for customer orders.

VALUE ADDED FEATURES

- Gate Management and Bay Allocation: Efficiently managing incoming and outgoing vehicles.

- 2D/3D Layout: Visualizing and optimizing warehouse layout for efficiency.

- Cross Docking: Directly transferring goods from receiving to outbound without storage.

- Kitting: Assembling product kits for efficient order fulfillment.

- Labor Management: Managing workforce scheduling and performance.

- Analytics and Reporting: Real-time monitoring of warehouse metrics and data-driven decision-making.

- IoT Integration: Integrating IoT devices for real-time data on inventory and equipment.

- ERP Integration: Seamlessly integrating with ERP systems for data accuracy and coordination.

A Warehouse Management System is not just a software application; it's a strategic tool that empowers businesses to achieve their primary objectives of enhancing efficiency, reducing costs, and improving customer service. By optimizing warehouse operations, providing real-time visibility, and offering scalability, WMS has become indispensable in today's competitive business landscape. Its implementation is a testament to a commitment to operational excellence and delivering superior value to customers. As technology continues to advance, the role of WMS in shaping the future of warehousing and distribution cannot be overstated.